There are many methods for glass forming, mainly including pressing method, drawing method, rolling method, casting method and the like.

First, the suppression method

Pressing method: a method in which a molten glass is injected into a mold, a mold ring is placed, a punch is pressed in, and a product is formed between the punch and the mold ring and the mold.

Process characteristics

Advantages:

Accurate shape, outer pattern products, simple process and high production capacity

Disadvantages:

1. The inner cavity of the product cannot be enlarged downwards, otherwise the punch cannot be taken out, and the side wall of the inner cavity cannot have a convex or concave place;

2. It is not possible to produce products with thin walls and inner cavities that are long in the vertical direction;

3, the surface of the product is not smooth, often with spots and mold seams;

Application: Solid and hollow glass products, glass bricks, water cups, vases, tableware, etc.

Second, the drawing method

Drawing method: It is a method of injecting molten glass into a model and drawing it into a product by a mechanical means through a cooler.

Application: Mainly used in the production of glass tubes, rods, flat glass, glass fiber, etc.

Third, the calendering method

The rolling method is a method of calendering a molten glass liquid between rolls or rolls to form a glass product.

Application: thick flat glass, engraved glass, wired glass, etc.

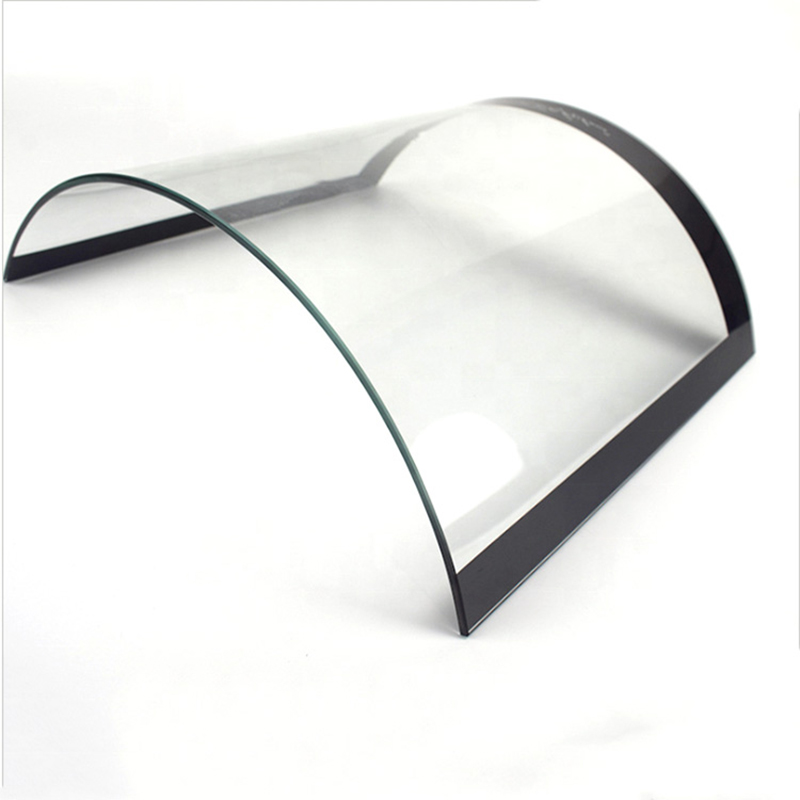

Fourth, casting method

Casting method: a method in which a molten glass liquid is injected into a mold, cooled by annealing, and processed to obtain a product.

Process characteristics: low equipment requirements, small product restrictions, suitable for large-scale products, but the accuracy of products is poor.

Main applications: art carving, architectural decorations, large diameter glass tubes, reaction pots.

Address: No.99,Gongfu 4th Road,Rhino Nikpo,Dalang Town,Dongguan City

Address: No.99,Gongfu 4th Road,Rhino Nikpo,Dalang Town,Dongguan City Business Hotline: 159 9979 3124

Business Hotline: 159 9979 3124 Website: www.kunhaoglass.com

Website: www.kunhaoglass.com E-mail: kunhaoglass@163.com

E-mail: kunhaoglass@163.com